How Does EVE Ensure the Safety of The MB31 3.2V LiFePO4 Battery?

2025.05.28

Safety is EVE’s top objective as we increase our LiFePO4 battery worldwide reach. EVE uses up-to-date Battery Management Systems (BMS) to monitor voltage, temperature, and current. Such monitoring avoids overcharging, over-discharging, and short circuits. Moreover, EVE’s automated manufacturing procedures assure quality, minimizing internal faults that might threaten safety. We use thermally stable materials to reduce thermal runaway risks. EVE batteries are safe and high-performing thanks to these technological precautions.

Common Defects of Low-Quality LiFePO4 Batteries Solved by EVE

Mitigating Dust Contamination in LiFePO4 Battery Production

Dust particles can affect LiFePO4 battery systems with impurities that prompt internal short circuits or tainted performance. We have implemented cleanroom standards during electrode preparation and cell assembly to address this. Air filtration systems and monitoring guarantee negligible particulate presence. Also, our automated material handling lowers human intervention to limit dust exposure. It boosts the reliability of our LiFePO4 battery systems.

Addressing Burr Formation in LiFePO4 Battery Manufacturing

Burrs are tiny metal fragments. They can emerge during electrode cutting and puncture separators and cause internal short circuits. We utilize slitting and die-cutting equipment to lower burr formation. Electrodes go through inspections using high-resolution imaging systems to remove any residual burrs. It assures the structural safety of our LiFePO4 battery systems.

Preventing False Soldering in LiFePO4 Battery Assembly

False soldering from weak or incomplete solder joints can trigger electrical failures or increased resistance in LiFePO4 battery systems. We employ automated soldering systems that give consistent temperature control and solder application to combat this. Each solder joint is inspected using automated optical inspection systems to verify adhesion and conductivity. Such a process guarantees the electrical steadfastness of our LiFePO4 battery systems.

Eliminating Leakage in LiFePO4 Battery Cells

Electrolyte leakage within LiFePO4 battery systems can cause performance and safety hazards. We have developed laser welding and high-precision crimping for airtight cell enclosures. Each cell endures pressure decay tests to detect leaks. With control over the sealing process, we provide the permanence and safety of our LiFePO4 battery systems.

Controlling Moisture Levels in LiFePO4 Battery Production

Superfluous moisture during manufacturing can affect the electrochemical stability of LiFePO4 battery systems. For that purpose, we conduct electrode drying processes in controlled environments to confiscate residual solvents. Cells are assembled in low-humidity conditions. They experience a baking process to reject any remaining moisture. Such moisture control protocols deliver the optimal performance and protection of our LiFePO4 battery systems.

FAQs about LiFePO4 Batteries

How to Keep LiFePO4 Batteries Safe during Shipping

Shipping LiFePO4 battery systems must diminish short circuits, mechanical damage, and thermal events. Confirm that each battery terminal is insulated to avert accidental shorting. Use non-conductive caps or high-grade insulating tape. For packaging, utilize anti-static bags and padding materials with a high resistance to puncture, including closed-cell polyethylene foam. It thwarts physical damage during handling. Follow UN 38.3 transportation testing standards.

Such standards include tests for altitude simulation, thermal shock, and vibration to assess a battery's resilience under shipping conditions. If it is shipping by air, compliance with IATA Dangerous Goods Regulations is key. For example, LiFePO4 battery systems with energy above 100Wh must be declared Class 9 hazardous materials and packed in strong, flame-resistant containers. Apart from that, include Material Safety Data Sheets (MSDS) with shipments while specifying safety protocols in case of spillage or fire. Finally, label packages with handling instructions, like "Handle with Care" and "Do Not Stack," to cut risks during transit.

What Are LiFePO4 Battery Safety Precautions?

When using LiFePO4 battery systems, safety precautions should inhibit thermal runaway, overcharging, and mechanical damage. A BMS for LiFePO4 chemistry should be integrated. A high-quality BMS monitors voltage, current, and temperature so cells are within safe active limits. E.g., it cuts off charging if the voltage is above 3.65V per cell or discharges below 2.5V. Likewise, avoid exposing batteries to temperatures beyond their rated range. Excessive heat can degrade the lithium iron phosphate structure. Freezing conditions may lower ionic conductivity.

Plus, enclosures with venting should manage gas release during thermal events. Use only chargers for LiFePO4 chemistry. Mismatched chargers can cause overcharging or incorrect balancing. During installation, confirm torque settings on terminal bolts to avoid loose connections, which can generate localized heating. Inspect batteries for signs of swelling, corrosion, or electrolyte leakage since they indicate internal damage. While following such precautions, the reliability of LiFePO4 battery systems is heightened.

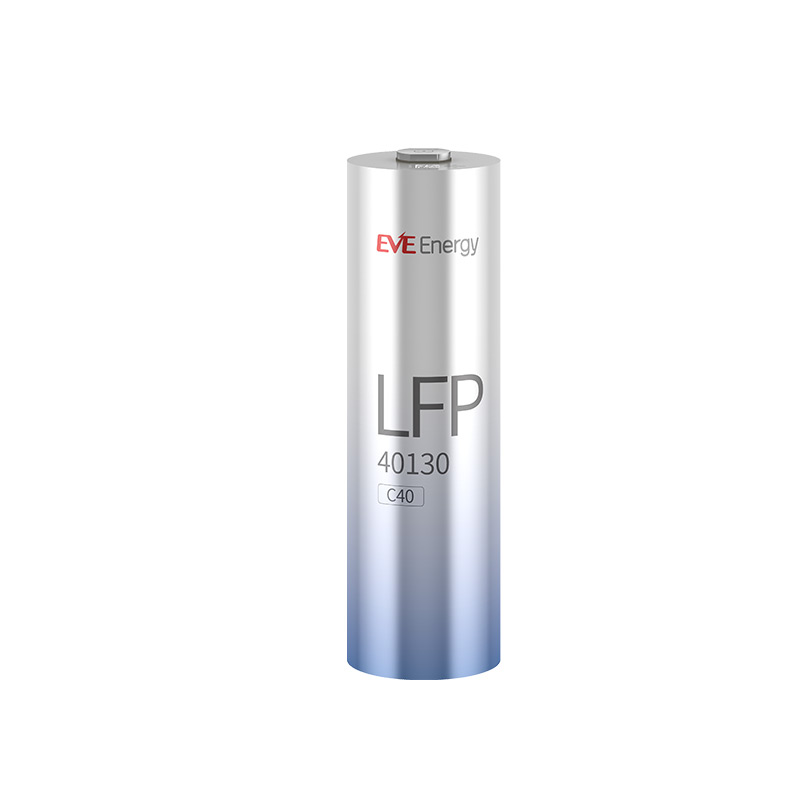

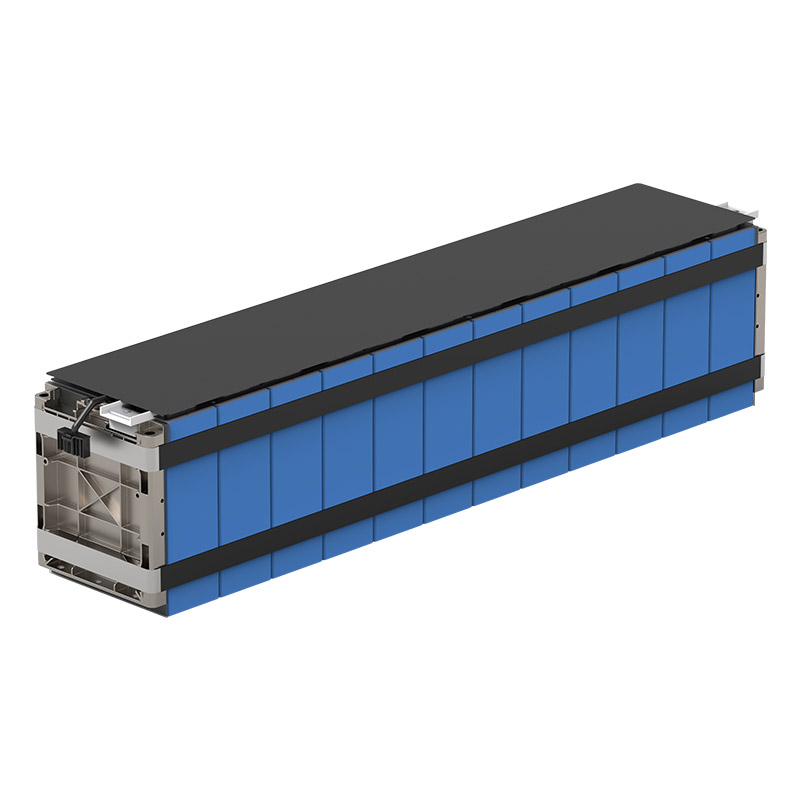

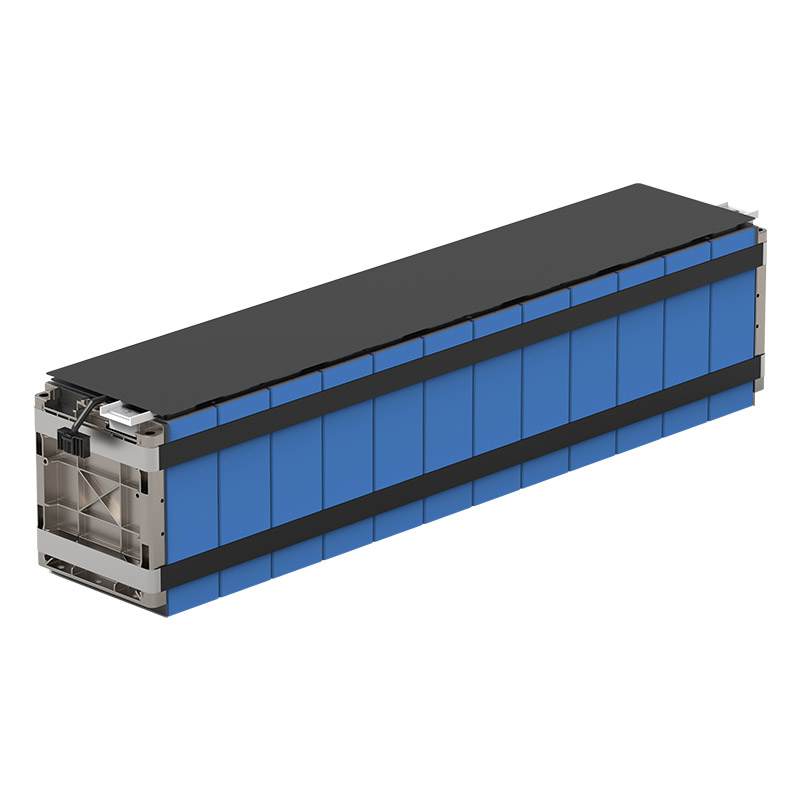

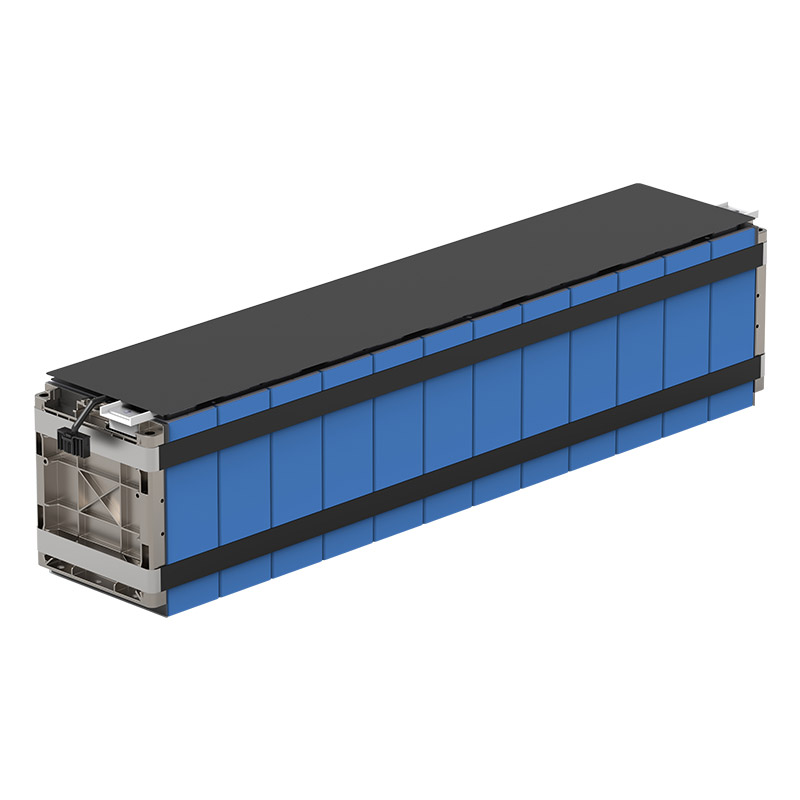

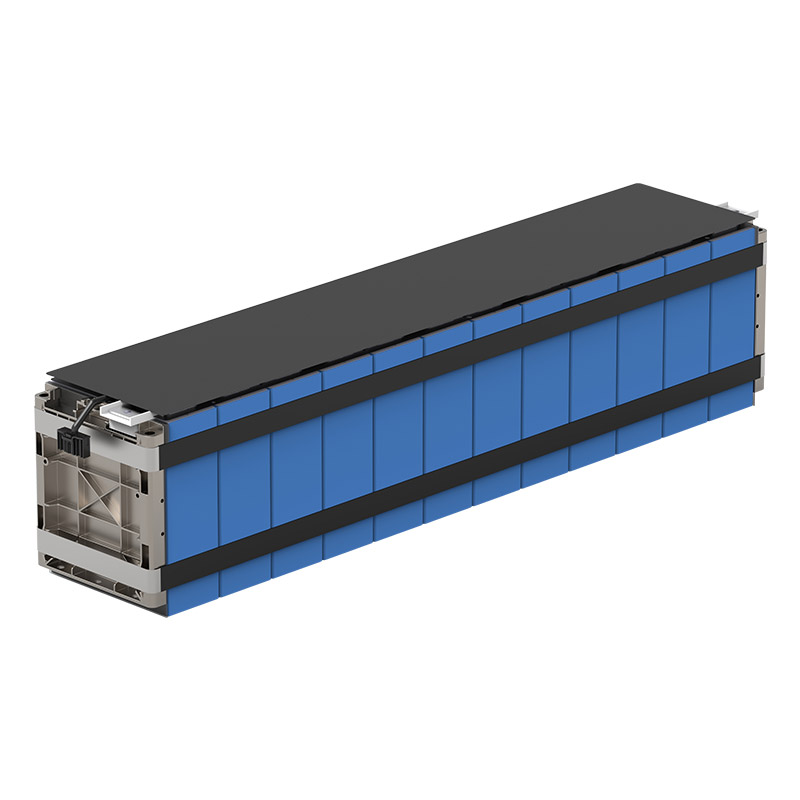

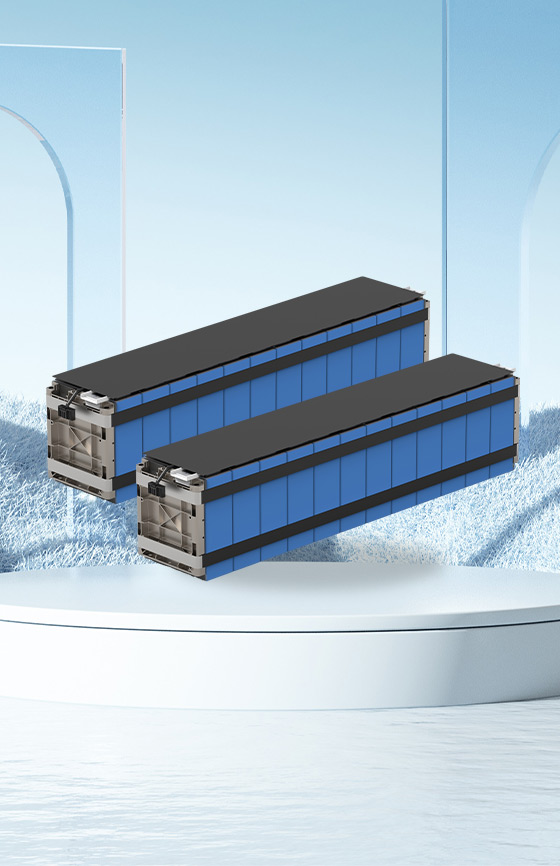

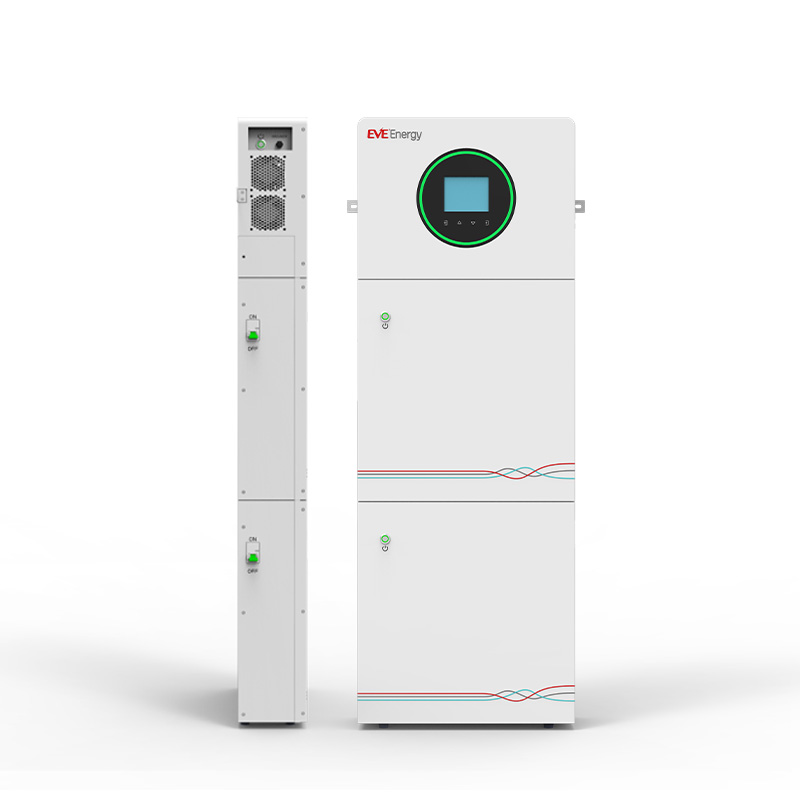

Safe and Powerful MB31 3.2v LiFePO4 Battery Cell

The MB31 3.2V LiFePO4 battery has a nominal capacity of 314Ah and an initial internal resistance of 0.18 mΩ (±0.05 mΩ). It weighs 5,600g (±300g), with 207.2mm height (with terminals), 173.7mm length, and 71.7mm thickness. The cell charges from 0 to 60°C and discharges from -30 to 60°C. A standard charging and discharging power of 0.5P is supported by a 3.65V charging cut-off voltage and a 2.5V or 2.0V discharging cut-off voltage (for temperatures above or below 0°C). The MB31's 8,000 cycles suit demanding applications.

Wrapping UP

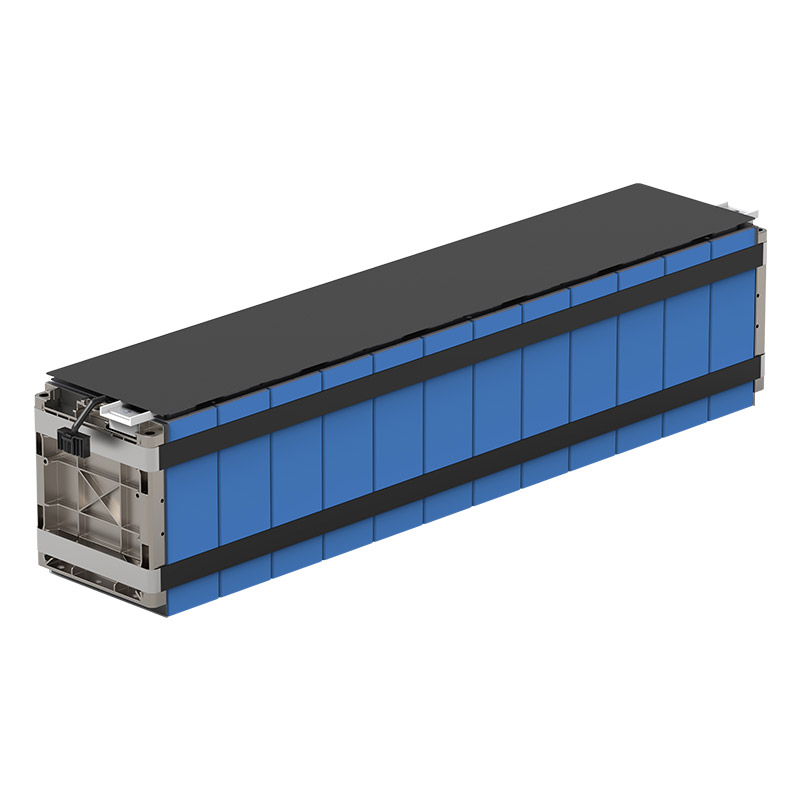

EVE ensures the safety of its MB31 3.2V LiFePO4 Battery through advanced LiFePO4 chemistry, which minimizes risks of thermal runaway and combustion. Rigorous quality control, including pre-shipment inspections and batch testing, ensures performance metrics like cycle life and thermal stability.

The battery’s prismatic aluminum casing, explosion-proof valves, and isolation coatings prevent short circuits and leakage. Certified to UN38.3, CE, and RoHS standards, the MB31 operates reliably. EVE’s focus on material innovation and automated production guarantees consistency, making the MB31 a safe, durable choice for energy storage and electric vehicles.

Related Content:

-

EVE MB31 vs. MB30 vs. 280K-V3 in Commercial ESS

EVE MB31 vs. MB30 vs. 280K-V3 in Commercial ESS2025.05.28

-

4 Types of Industrial Energy Storage Technologies You Should Know

4 Types of Industrial Energy Storage Technologies You Should Know2025.05.28

-

The Significance of Lithium Boat Battery: Why, What, And How

The Significance of Lithium Boat Battery: Why, What, And How2025.05.28

-

How Does Household Energy Storage Keep the Lights on During Power Outage?

How Does Household Energy Storage Keep the Lights on During Power Outage?2025.05.28

-

LiFePO4 vs. Lead Acid: Performance, Applications and Supply Chain

LiFePO4 vs. Lead Acid: Performance, Applications and Supply Chain2025.05.27

-

EVE LiFePO4 State of Charge Chart & Discharge Curve & Capacity Diagrams

EVE LiFePO4 State of Charge Chart & Discharge Curve & Capacity Diagrams2025.05.27