The Importance of Standardization in Cylindrical Cells

2025.08.07

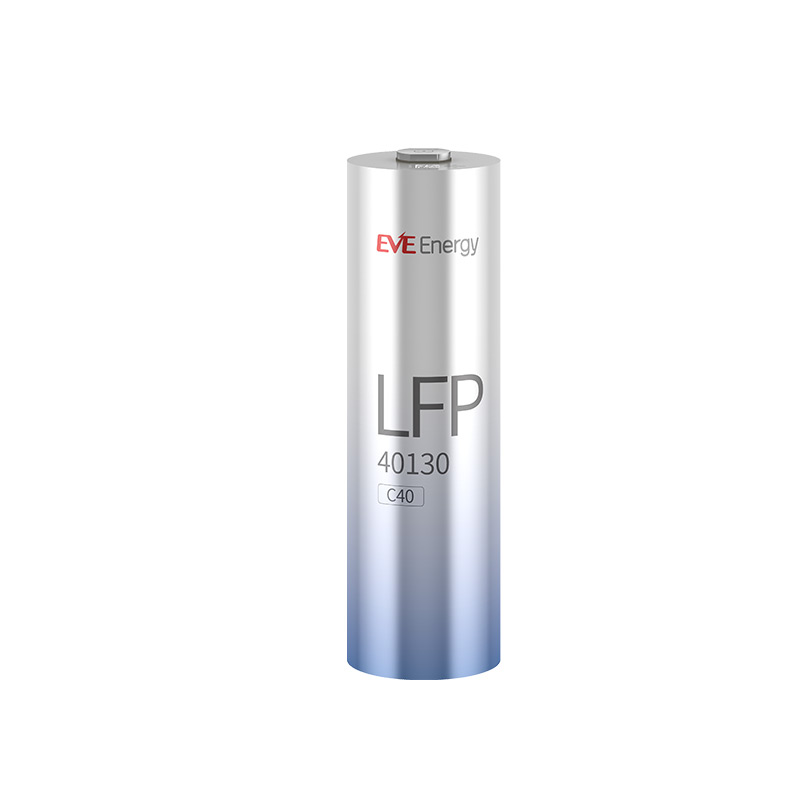

One of the significant advantages of the cylindrical battery cell design lies in the standardization of manufacturing processes. This standardization is crucial in ensuring that each battery produced maintains consistent quality and performance metrics. For EVE Energy, this commitment to standardization translates into efficient production workflows, leading to shorter process paths and improved quality control.

By adhering to standardized protocols, EVE can implement rigorous testing and quality assurance measures throughout the manufacturing process. This ensures that every ICR18650 battery meets high standards for safety, efficiency, and reliability. The benefits of standardization extend beyond just quality; they also enhance the scalability of production. As demand for cylindrical cells grows, EVE can ramp up production without compromising on the quality that consumers expect.

Moreover, standardized components allow for easier integration into various applications and devices. Manufacturers utilizing EVE’s batteries can design their products with confidence, knowing that the cylindrical cells will deliver consistent performance. This reliability fosters trust and encourages broader adoption of EVE’s technology across different industries.

Lifecycle Efficiency

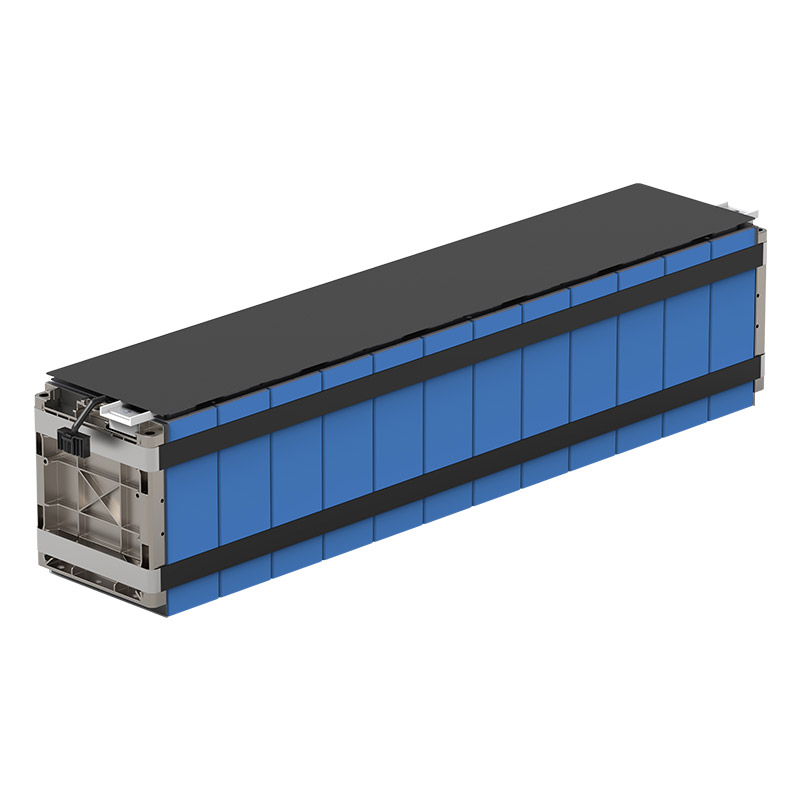

Cylindrical cells, particularly the EVE 18650, are designed for longevity and lifecycle efficiency. One of the standout features of these batteries is their life cycle that emphasizes zero stress. This design philosophy ensures that the cells maintain their integrity over time, making them suitable for demanding applications. The ability to endure over 1000 cycles without significant degradation means that users can rely on EVE batteries for prolonged periods, reducing the need for frequent replacements.

This focus on durability is crucial, especially when cylindrical cells are used in devices that require a reliable power source, such as cameras, power tools, and excavators. In applications where performance is critical, having a battery that can withstand the rigors of daily use without failing ensures that devices function optimally. EVE's commitment to lifecycle efficiency not only enhances user satisfaction but also contributes to a more sustainable approach to energy storage.

Environmental Considerations

EVE is also dedicated to ensuring that their cylindrical cells are manufactured with environmental impact in mind. The company understands the growing demand for environmentally-friendly technologies and has taken steps to optimize the materials used in their batteries. By carefully selecting components and minimizing waste during the manufacturing process, EVE has improved the overall sustainability of their products.

Additionally, EVE’s focus on standardization aids in enhancing the recycling process for their cylindrical cells. Standardized components make it easier to disassemble and recycle batteries, thereby reducing landfill waste and promoting a circular economy. This commitment to environmental responsibility is not only beneficial for the planet but also aligns with consumer preferences for sustainable products.

As regulations around battery disposal and recycling become more stringent, EVE’s proactive approach positions them favorably within the industry. Their efforts to balance performance with environmental considerations demonstrate a forward-thinking strategy that appeals to both consumers and regulators alike.

Conclusion

In conclusion, the cylindrical cell design, particularly exemplified by the ICR18650 battery, represents a blend of efficiency, safety, and environmental responsibility. EVE’s approach to standardization and quality assurance ensures that their cylindrical battery cells will continue to meet the needs of consumers and industries alike. By emphasizing lifecycle efficiency and environmental considerations, EVE not only enhances the durability and performance of their batteries but also contributes positively to global sustainability efforts.